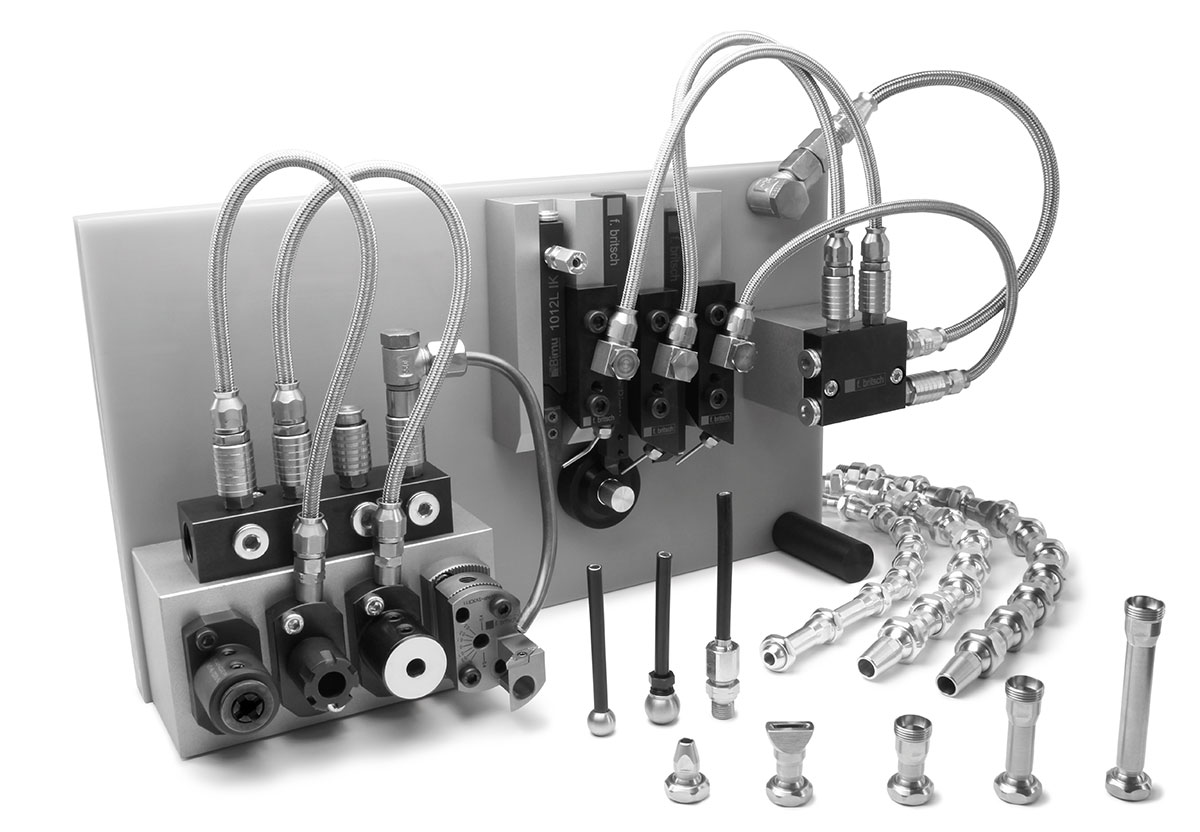

D60 mobile circular plate

So that everything runs smoothly in 2025… Start the new year with a production booster at a special price! The popular D60 mobile circular plate incl. POM plate now costs just € 5,850 and supports your production with: + Extremely easy operation – ready for immediate use + Flexible cycle & speed – individually adjustable + No oil chaos – thanks to integrated return hose + Parts baskets – not required and therefore do not need to be emptied regularly The popular D60 is 10% cheaper for you at the start of the year. The special price is valid until 28.02.2025, only while available. /* "function"==typeof InitializeEditor,callIfLoaded:function(o){return!(!gform.domLoaded||!gform.scriptsLoaded||!gform.themeScriptsLoaded&&!gform.isFormEditor()||(gform.isFormEditor()&&console.warn("The use of gform.initializeOnLoaded() is deprecated in the form editor context and will be removed in Gravity Forms 3.1."),o(),0))},initializeOnLoaded:function(o){gform.callIfLoaded(o)||(document.addEventListener("gform_main_scripts_loaded",()=>{gform.scriptsLoaded=!0,gform.callIfLoaded(o)}),document.addEventListener("gform/theme/scripts_loaded",()=>{gform.themeScriptsLoaded=!0,gform.callIfLoaded(o)}),window.addEventListener("DOMContentLoaded",()=>{gform.domLoaded=!0,gform.callIfLoaded(o)}))},hooks:{action:{},filter:{}},addAction:function(o,r,e,t){gform.addHook("action",o,r,e,t)},addFilter:function(o,r,e,t){gform.addHook("filter",o,r,e,t)},doAction:function(o){gform.doHook("action",o,arguments)},applyFilters:function(o){return gform.doHook("filter",o,arguments)},removeAction:function(o,r){gform.removeHook("action",o,r)},removeFilter:function(o,r,e){gform.removeHook("filter",o,r,e)},addHook:function(o,r,e,t,n){null==gform.hooks[o][r]&&(gform.hooks[o][r]=[]);var d=gform.hooks[o][r];null==n&&(n=r+"_"+d.length),gform.hooks[o][r].push({tag:n,callable:e,priority:t=null==t?10:t})},doHook:function(r,o,e){var t;if(e=Array.prototype.slice.call(e,1),null!=gform.hooks[r][o]&&((o=gform.hooks[r][o]).sort(function(o,r){return o.priority-r.priority}),o.forEach(function(o){"function"!=typeof(t=o.callable)&&(t=window[t]),"action"==r?t.apply(null,e):e[0]=t.apply(null,e)})),"filter"==r)return e[0]},removeHook:function(o,r,t,n){var e;null!=gform.hooks[o][r]&&(e=(e=gform.hooks[o][r]).filter(function(o,r,e){return!!(null!=n&&n!=o.tag||null!=t&&t!=o.priority)}),gform.hooks[o][r]=e)}}); /* ]]> */ Anfrageformular Rundteller D60 ENGLISCH LinkedInThis field is for validation purposes and should be left unchanged.Company(Required)Contact person(Required) First name Second Name Contact Mailaddress(Required) Please enter your e-mail address here to receive the offer.Inquiry(Required) Rundteller D60 mit POM-Platte Pieces(Required)12345678910Data protection(Required) I consent to my data being stored for the purpose of processing my enquiry. My data will not be passed on to third parties and I can revoke my consent at any time. Information according to GDPR can be found in our privacy policy. /* = 0;if(!is_postback){return;}var form_content = jQuery(this).contents().find('#gform_wrapper_43');var is_confirmation = jQuery(this).contents().find('#gform_confirmation_wrapper_43').length > 0;var is_redirect = contents.indexOf('gformRedirect(){') >= 0;var is_form = form_content.length > 0 && ! is_redirect && ! is_confirmation;var mt = parseInt(jQuery('html').css('margin-top'), 10) + parseInt(jQuery('body').css('margin-top'), 10) + 100;if(is_form){form_content.find('form').css('opacity', 0);jQuery('#gform_wrapper_43').html(form_content.html());if(form_content.hasClass('gform_validation_error')){jQuery('#gform_wrapper_43').addClass('gform_validation_error');} else {jQuery('#gform_wrapper_43').removeClass('gform_validation_error');}setTimeout( function() { /* delay the scroll by 50 milliseconds to fix a bug in chrome */ }, 50 );if(window['gformInitDatepicker']) {gformInitDatepicker();}if(window['gformInitPriceFields']) {gformInitPriceFields();}var current_page = jQuery('#gform_source_page_number_43').val();gformInitSpinner( 43, 'https://f-britsch.com/wp-content/plugins/gravityforms/images/spinner.svg', true );jQuery(document).trigger('gform_page_loaded', [43, current_page]);window['gf_submitting_43'] = false;}else if(!is_redirect){var confirmation_content = jQuery(this).contents().find('.GF_AJAX_POSTBACK').html();if(!confirmation_content){confirmation_content = contents;}jQuery('#gform_wrapper_43').replaceWith(confirmation_content);jQuery(document).trigger('gform_confirmation_loaded', [43]);window['gf_submitting_43'] = false;wp.a11y.speak(jQuery('#gform_confirmation_message_43').text());}else{jQuery('#gform_43').append(contents);if(window['gformRedirect']) {gformRedirect();}}jQuery(document).trigger("gform_pre_post_render", [{ formId: "43", currentPage: "current_page", abort: function() { this.preventDefault(); } }]); if (event && event.defaultPrevented) { return; } const gformWrapperDiv = document.getElementById( "gform_wrapper_43" ); if ( gformWrapperDiv ) { const visibilitySpan = document.createElement( "span" ); visibilitySpan.id = "gform_visibility_test_43"; gformWrapperDiv.insertAdjacentElement( "afterend", visibilitySpan ); } const visibilityTestDiv = document.getElementById( "gform_visibility_test_43" ); let postRenderFired = false; function triggerPostRender() { if ( postRenderFired ) { return; } postRenderFired = true; gform.core.triggerPostRenderEvents( 43, current_page ); if ( visibilityTestDiv ) { visibilityTestDiv.parentNode.removeChild( visibilityTestDiv ); } } function debounce( func, wait, immediate ) { var timeout; return function() { var context = this, args = arguments; var later = function() { timeout = null; if ( !immediate ) func.apply( context, args ); }; var callNow = immediate && !timeout; clearTimeout( timeout ); timeout = setTimeout( later, wait ); if ( callNow ) func.apply( context, args ); }; } const debouncedTriggerPostRender = debounce( function() { triggerPostRender(); }, 200 ); if ( visibilityTestDiv && visibilityTestDiv.offsetParent === null ) { const observer = new MutationObserver( ( mutations ) => { mutations.forEach( ( mutation ) => { if ( mutation.type === 'attributes' && visibilityTestDiv.offsetParent !== null ) { debouncedTriggerPostRender(); observer.disconnect(); } }); }); observer.observe( document.body, { attributes: true, childList: false, subtree: true, attributeFilter: [ 'style', 'class' ], }); } else { triggerPostRender(); } } );} ); /* ]]> */