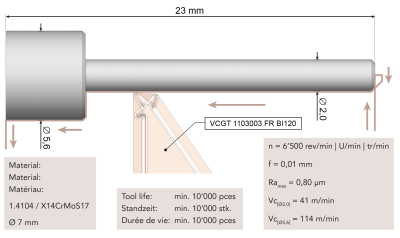

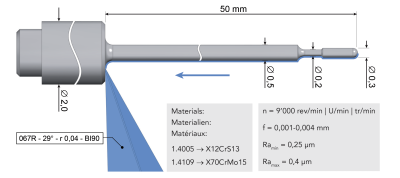

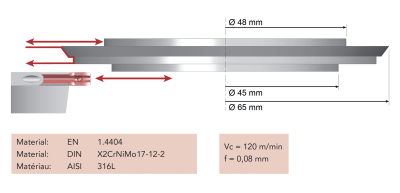

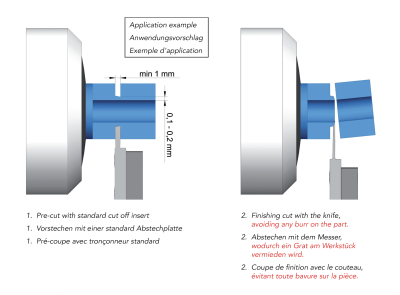

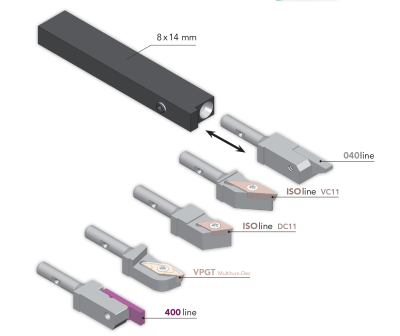

With extended geometries for inserts, holder systems and cutting tools, Bimu provides real solutions for classic challenges in tool life and cutting on sliding headstock automatic lathes.

As the largest Bimu trading partner, we are absolutely convinced of the new efficient cutting geometries and tool holders. We present tools with success stories and, as always, will be happy to advise you personally on the entire Bimu range.