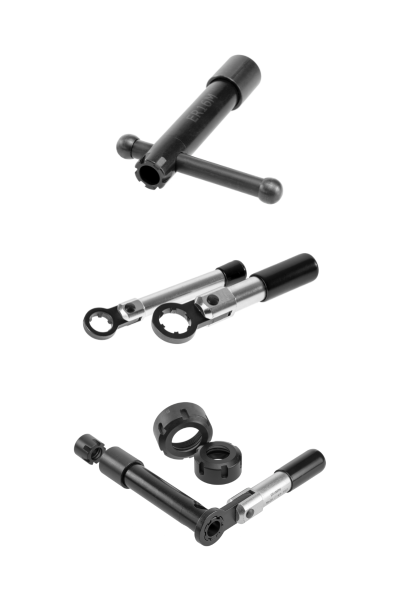

3. Wrench for ER clamping nuts

The choice, functionality and quality of the tools used make a significant contribution to work safety. The best way to explain this is in practical terms using our torque wrench.

The field of application is clear: the operator uses the wrench to tighten ER nuts in the lathe, for example when changing tools. Due to the predefined force when tightening the nut with repeat accuracy, concentricity errors and over-tightening are reduced. In addition, damage to the tool holder and the nut itself is avoided because it is not overtightened and slipping during the clamping process is virtually impossible. And with that we have named the moment of risk of injury: The risk of slipping due to excessive force being applied when tightening is averted when using a torque wrench. In addition, there is no need to correct (in the event of concentricity errors or over-tightening) by unclamping and re-tightening.

The socket wrench compensates for the limited space available in the lathe.

Non-slip, easier operation and, paired with the torque wrench, an optimum solution for simple tool changes.

View wrenches for ER clamping nuts in the f.britsch online store

Conclusion

As a trading partner for the turned parts industry, it is very important to us to consider occupational health and safety for machine operators. We face up to this responsibility as a supplier.