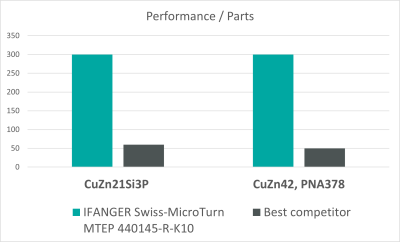

Success Story: 5x longer in lead-free brass

Challenge

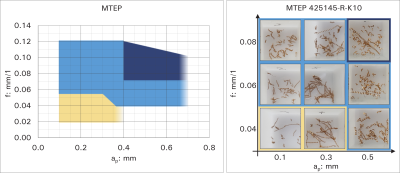

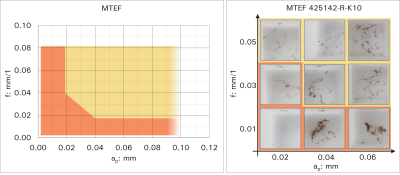

The restriction of leaded free-cutting brass is forcing manufacturers in drinking water applications and the watch and jewelry industry to use alternative materials such as CuZn21Si3P and CuZn42. These ‘lead-free’ variants have higher strength values, but pose a challenge. CuZn21Si3P in particular, with added abrasive silicon, stresses tool cutting edges and shortens their service life. Despite difficult machining properties, the challenge is to develop durable tools that also offer process-reliable chip control in order to prevent ribbon and tangled chips as well as ‘chip nests’.

Solution

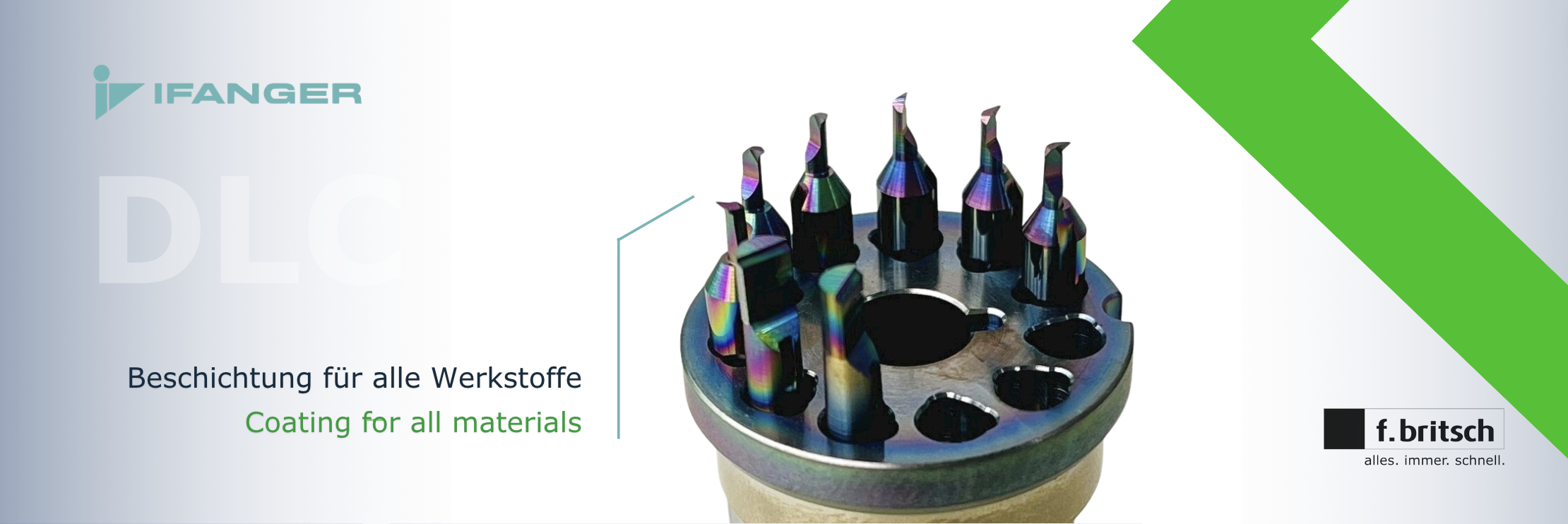

With the new Swiss-MicroTurn MTEP line, IFANGER has created pioneering micro internal turning tools that are significantly superior to comparable products from the competition in terms of cutting ability, chip control and durability.

Benchmark, Performance comparison

Bore according to drawing