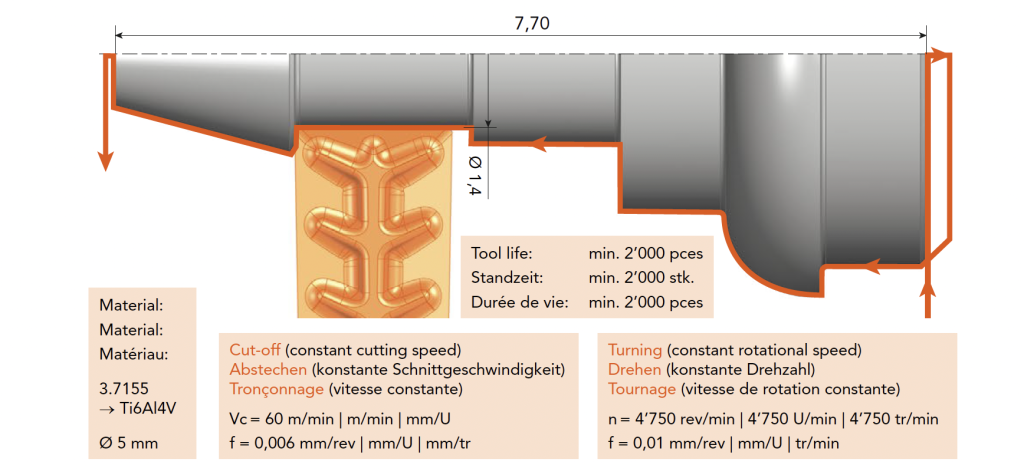

When you learn from others, you don’t have to find solutions to challenges that others have already solved in their production under very similar conditions. In this case, the challenge was to optimize the manufacturing process for a titanium component used in medical technology.

The challenge: stable production of large quantities

The turning shop manufactures tens of thousands of parts per year. Series production must run stably and reliably around the clock, day and night. This means that precise face turning and parting off are required. Long, tangled chips are not permitted. The goal is excellent chip control. In addition, the entire turning contour should be produced with a single tool. The economic aspect was also under discussion: the service life of the tool should be increased.